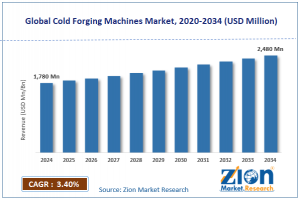

Global Cold Forging Machines Market to Reach USD 2,480 Million by 2034, Growing at 3.4% CAGR

The global cold forging machines market size was worth around USD 1,780 million in 2024 and is predicted to grow to around USD 2,480 million by 2034

Global cold forging machines market size was worth around USD 1,780 million in 2024 and is predicted to grow to around USD 2,480 million by 2034 (CAGR) of roughly 3.4% between 2025 and 2034. ”

PUNE, MAHARASHTRA, INDIA, January 21, 2026 /EINPresswire.com/ -- The global cold forging machines market size is experiencing steady growth, driven by increasing demand from automotive, aerospace, construction, and industrial machinery sectors, as well as rising adoption of precision manufacturing processes. In 2024, the global cold forging machines market was valued at approximately USD 1,780 million and is projected to reach around USD 2,480 million by 2034, growing at a compound annual growth rate (CAGR) of roughly 3.4% between 2025 and 2034.— Deepak Rupnar

Access key findings and insights from our Report in this Free sample -https://www.zionmarketresearch.com/sample/cold-forging-machines-market

Cold forging is a manufacturing process that deforms metal at room temperature to create precise, high-strength parts with minimal material waste. This technique offers several advantages over traditional hot forging, including enhanced dimensional accuracy, improved surface finish, higher productivity, and energy efficiency. These benefits make cold forging machines increasingly popular in industries that require precision-engineered components.

As global industrialization continues, manufacturers are focusing on process optimization, cost reduction, and high-quality output, which is further driving the adoption of advanced cold forging machines.

Market Overview

Cold forging machines are used to produce components such as bolts, nuts, fasteners, screws, gears, shafts, and other precision parts from metals such as steel, aluminum, copper, and titanium. Unlike hot forging, cold forging is performed at ambient temperatures, which strengthens the metal through work hardening while reducing the need for secondary machining and finishing.

Key applications of cold forging machines include:

Automotive components such as engine parts, transmission shafts, and fasteners

Aerospace components i, including structural parts and landing gear components

Industrial machinery and heavy equipment components

Construction hardware such as bolts, nuts, and anchors

Electrical and electronic components requiring high-dimensional precision

The market’s growth is driven by rising demand for lightweight and high-strength metal components, increased automation in manufacturing, and growing focus on environmentally friendly, energy-efficient production techniques. With the market projected to expand from USD 1,780 million in 2024 to USD 2,480 million by 2034, cold forging machines are expected to play a critical role in modern manufacturing operations.

Key Market Drivers

1. Expansion of Automotive and Aerospace Industries

The automotive and aerospace sectors are the largest consumers of cold forged components. Rising vehicle production, increasing demand for lightweight parts, and the adoption of electric vehicles requiring precision-engineered fasteners and components are driving market growth.

2. Rising Demand for High-Precision Components

Cold forging machines deliver consistent, high-quality parts with tight tolerances. Industries that require high-strength, precision components are increasingly adopting cold forging over hot forging or machining.

3. Energy Efficiency and Cost Savings

Cold forging consumes less energy compared to hot forging since it eliminates the need for heating. Additionally, material utilization is optimized, reducing waste and lowering production costs.

4. Technological Advancements in Machinery

Modern cold forging machines are equipped with CNC control systems, automation, multi-station capabilities, and real-time monitoring, increasing efficiency and accuracy. These advancements are driving adoption across industries.

5. Industrial Automation and Smart Manufacturing

The push toward Industry 4.0, automation, and digital manufacturing is encouraging manufacturers to adopt advanced cold forging machines that integrate with production line control systems for process optimization and predictive maintenance.

Do You Have Any Query Or Specific Requirement? Request Customization of Report:-https://www.zionmarketresearch.com/custom/9928

Market Segmentation

By Machine Type

Single-Station Cold Forging Machines

Multi-Station Cold Forging Machines

CNC-Controlled Cold Forging Machines

Hydraulic Cold Forging Machines

Mechanical Cold Forging Machines

Multi-station and CNC-controlled machines dominate the market due to higher throughput, automation capabilities, and precision control.

By Application

Automotive Components

Aerospace Components

Industrial Machinery Parts

Construction Hardware

Electrical and Electronics Components

Consumer Goods Components

The automotive sector represents the largest application segment, driven by demand for fasteners, shafts, and structural components.

By Metal Type

Steel

Aluminum

Copper

Titanium

Other Alloys

Steel remains the dominant material due to its strength and widespread use in automotive and industrial applications, while aluminum and titanium are growing in aerospace and EV sectors.

By End User

Automotive Manufacturers

Aerospace and Defense Companies

Industrial Machinery Manufacturers

Construction and Infrastructure Companies

Electronics and Electrical Equipment Manufacturers

Regional Analysis

Asia-Pacific

Asia-Pacific is the largest and fastest-growing market, driven by high production volumes in automotive, electronics, and heavy machinery sectors in China, India, Japan, and South Korea. The region also benefits from low manufacturing costs and extensive industrial infrastructure.

North America

North America is a mature market with significant demand from automotive, aerospace, and industrial equipment manufacturers. Growth is fueled by the adoption of advanced CNC-controlled machines and Industry 4.0 practices.

Europe

Europe represents a stable market, supported by automotive manufacturing hubs, aerospace engineering, and high-precision industrial machinery production. Demand for lightweight and high-strength components in EVs and aerospace drives growth.

Latin America

Latin America is witnessing moderate growth, with demand mainly from automotive, construction, and industrial machinery applications. Brazil and Mexico are key regional markets.

Middle East and Africa

The Middle East and Africa region is experiencing growth due to industrialization, infrastructure projects, and demand for construction hardware and machinery components. However, market penetration remains lower than in other regions.

Inquiry For Buying- https://www.zionmarketresearch.com/inquiry/cold-forging-machines-market

Cold Forging Machines Market: Competitive Analysis

The global cold forging machines market is dominated by players like:

Jern Yao

Chun Yu Group

National Machinery

Sacma

Sakamura

Hyodong

Carlo Salvi

Nakashimada

Komatsu

Nedschroef

Sunac

Tanisaka

GFM

Aida

Hatebur

MANYO

Stamtec

Shanghai Chun Yu Group

Ningbo Sijin Machinery

Tongyong

Qunfeng Machinery

Innor Machinery

Yeswin Group

The global cold forging machines market is moderately consolidated, with key players offering high-performance, automated, and precision-controlled machines. Competitive strategies include:

Development of energy-efficient and multi-station machines

Integration of CNC and robotic automation

Expansion of service networks and technical support

Strategic partnerships with automotive and industrial OEMs

Customization for specific metals and production requirements

Leading market players focus on innovation, reliability, and precision to maintain a competitive edge and meet the increasing demand for high-quality forged components.

Industry Trends

1. Increased Adoption of CNC and Automated Machines

Manufacturers are moving toward fully automated, CNC-controlled cold forging systems to improve productivity, reduce labor costs, and maintain consistent quality.

2. Lightweight Materials and EV Adoption

Rising demand for aluminum and titanium components in electric vehicles and aerospace is boosting the adoption of specialized cold forging machines capable of handling lightweight metals.

3. Digital Monitoring and Industry 4.0 Integration

Smart machines equipped with sensors, data analytics, and remote monitoring capabilities allow predictive maintenance and process optimization, enhancing operational efficiency.

4. Multi-Station and High-Speed Forging

Multi-station cold forging machines capable of high-speed operations are gaining popularity for mass production of fasteners, bolts, nuts, and shafts in automotive and industrial sectors.

5. Environmentally Friendly and Energy-Efficient Manufacturing

Cold forging eliminates the need for heating, reducing energy consumption and carbon footprint. Manufacturers are emphasizing energy-efficient and sustainable operations to comply with environmental regulations.

Challenges and Restraints

Despite steady growth, the market faces certain challenges:

High capital investment for advanced CNC and multi-station machines

Requirement for skilled operators and technicians

Limited flexibility for very complex part geometries

Maintenance and servicing in remote regions

Competition from hot forging and machining for certain applications

Addressing these challenges requires training, service support, and technological innovation to maintain machine efficiency and versatility.

Future Outlook

The global cold forging machines market is expected to witness moderate but steady growth through 2034, supported by:

Expansion of automotive, aerospace, and industrial machinery production

Rising demand for lightweight and high-strength components

Adoption of smart, automated, and CNC-controlled cold forging systems

Emphasis on cost-efficient, sustainable, and high-precision manufacturing

Increasing electrification in transportation and demand for advanced materials

As industrial sectors continue to prioritize efficiency, quality, and sustainability, cold forging machines will remain a key technology for producing high-precision metal components.

Conclusion

The global cold forging machines market is projected to grow from approximately USD 1,780 million in 2024 to around USD 2,480 million by 2034, registering a CAGR of roughly 3.4% between 2025 and 2034. Growth is driven by rising adoption in the automotive, aerospace, construction, and industrial machinery sectors, increasing demand for high-precision and lightweight components, and ongoing technological advancements in CNC and multi-station cold forging systems. With their ability to produce durable, high-quality parts efficiently and sustainably, cold forging machines will continue to play a critical role in modern manufacturing worldwide.

Browse Other Related Research Reports from Zion Market Research

Textile Yarn Market - by Source (Chemical, Animal, Plant, and Others), Application (Home Textile, Apparel, and Industrial), Type (Artificial (Viscose, Polyester, Acrylic, and Nylon), and Natural (Flax, Wool, Ramie, Cotton, Hemp, Jute, and Silk)): Global Industry Perspective, Comprehensive Analysis and Forecast, 2024 - 2032-https://www.zionmarketresearch.com/report/textile-yarn-market

Refrigerated Warehousing Market - by Technology (Vapor Compression, Evaporative Cooling, Blast Freezing, PLC), by Temperature (Chilled, Frozen), by Application (Bakery, Meat, Beverages, Fruits & Vegetables, Dairy, Seafood), and by Region: Global Industry Perspective, Comprehensive Analysis and Forecast, 2024 - 2032-https://www.zionmarketresearch.com/report/refrigerated-warehousing-market

Hybrid Fabric Market - by End-use Industry (Aerospace & Defense, Automotive & Transportation, and Wind Energy), by Fiber Type (Carbon/Uhmwpe, Glass/Carbon, Carbon/Aramid, and Glass/Aramid), by Application Form (Non-Composite and Composite), and by Region - Global Industry Perspective, Comprehensive Analysis, and Forecast, 2024 - 2032-https://www.zionmarketresearch.com/report/hybrid-fabric-market

Industrial Protective Fabrics Market - By Product (Disposable and Durable), By End-Use (Commercial, Residential, And Industrial), By Applications (Limited General-Use, Clean Room, Mechanical Protective, Flame Retardant Apparel, Chemical Defending Garments, And Others), And By Region - Global Industry Perspective, Comprehensive Analysis, And Forecast, 2024 - 2032-https://www.zionmarketresearch.com/report/industrial-protective-fabrics-market

Global Dehumidifier Market - By Technology (Warm Condensation, Sorption And Cold Condensation), By Product (Ventilating Dehumidifier, Heat Pump, And Chemical Absorbent), By Application (Industrial, Commercial, And Residential), And By Region- Global Industry Perspective, Comprehensive Analysis, and Forecast, 2024 - 2032-https://www.zionmarketresearch.com/report/dehumidifier-market

Digital Servo Press Market by Type (100 KN, Between 100 KN and 200 KN, and More than 200 KN), by Application (Automotive, Motor & Electronics, Aerospace, Medical Equipment, and Robotics Sector), by Motor Type (Positional Rotation, Linear Rotation, and Continuous Rotation), and by Region: Global Industry Perspective, Comprehensive Analysis and Forecast, 2024 - 2032-https://www.zionmarketresearch.com/report/digital-servo-press-market

Construction Flooring Chemicals Market - By Product (Epoxy, Vinyl, Polyurethanes, and Poly Methyl Methacrylate (PMMA)), By Type (Soft Covering, Resilient, Non-Resilient, and Others), By Application (Residential, Commercial, Infrastructure, and Repair Structure), and By Region: Global Industry Perspective, Comprehensive Analysis and Forecast, 2024 - 2032-https://www.zionmarketresearch.com/report/construction-flooring-chemicals-market

Cosmetic Antioxidants Market - by Type (Vitamin A, Vitamin C, Vitamin E, Enzymes, Polyphenols, and Carotenoids), Source (Chemically Derived Antioxidants, and Natural Antioxidants), and Function (Anti-Inflammatory, UV Protection, Moisturizing, Hair Cleansing, Anti-Aging, Hair Conditioning, and Others) Application (Haircare, Skincare, And Makeup): Global Industry Perspective, Comprehensive Analysis and Forecast 2024 - 2032-https://www.zionmarketresearch.com/report/cosmetic-antioxidants-market

Shampoo Market - by Type (Anti-Dandruff Shampoo, Cosmetic Shampoo, Dry Shampoo, Herbal Shampoo, Baby Care Shampoo, Animal Shampoo, Antibacterial Shampoo, and Others): Global Industry Perspective, Comprehensive Analysis and Forecast, 2024 - 2032-https://www.zionmarketresearch.com/report/shampoo-market

Medical Furniture Market - by Products (Beds, Chairs, Trolleys & stretches, Tables and Cabinets & lockers), Material (Wood, Plastics and Metal), End-user (Hospitals, Home healthcare and Ambulatory surgical Centres): Global Industry Perspective, Comprehensive Analysis and Forecast, 2024 - 2032-https://www.zionmarketresearch.com/report/medical-furniture-market

Deepak Rupnar

Zion Market Research

+1 855-465-4651

richard@zionmarketresearch.com

Visit us on social media:

LinkedIn

Instagram

Facebook

YouTube

X

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.